Navigating the intricate world of international logistics can be challenging, but with the right strategies in place, you can significantly cut down on shipment costs. This guide will walk you through essential tactics to optimize your logistics operations and save money.

1. Optimize Inventory Management

Effective inventory management is a cornerstone strategy for reducing shipping costs. Consider the balance: if you overstock, you incur unnecessary storage fees and risk obsolescence. Conversely, understocking can lead to costly expedited shipping to meet demands. By maintaining optimal stock levels, businesses can minimize costs while ensuring timely order fulfillment. A move towards a lean inventory can be supported by technologies such as inventory management software that tracks stock levels in real-time and provides data-driven insights for future planning. This approach not only cuts costs but also aligns with the broader goal of improving your supply chain efficiency.

Involving your entire team in the inventory management process is equally important. Regular training sessions can empower your staff to handle inventory more efficiently. Teams that understand logistics intricacies are more adept at forecasting demand and identifying potential bottlenecks before they become issues, streamlining operations further. In short, by fostering a culture of transparency and shared responsibility, you create an environment where inventory flows smoothly, ultimately saving costs on both storage and shipping.

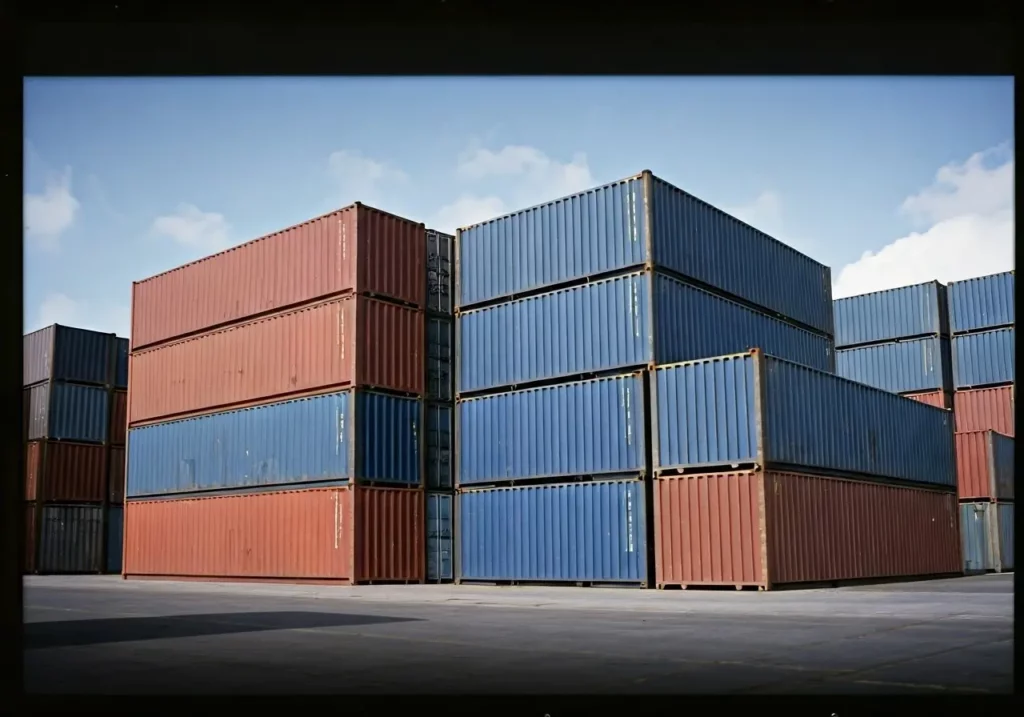

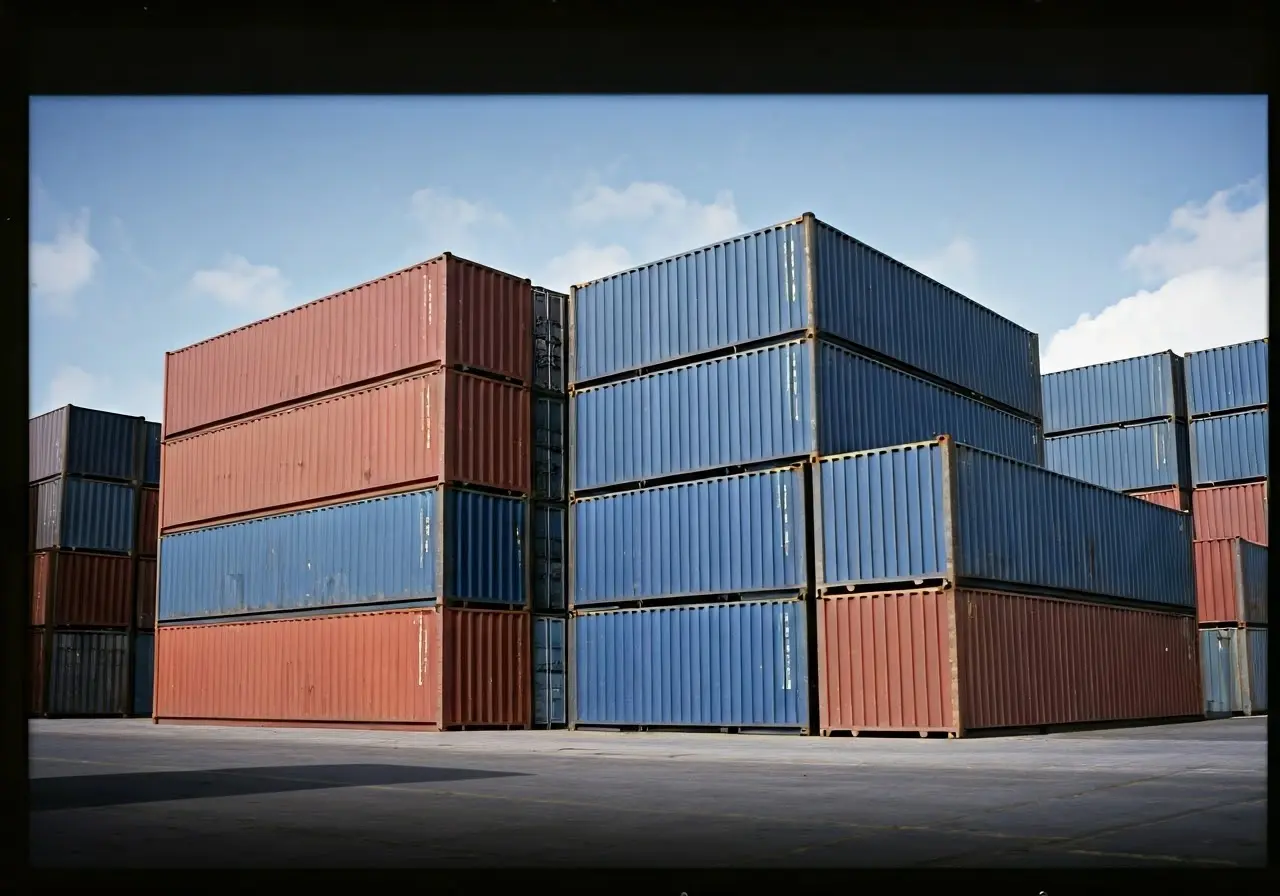

2. Leverage Freight Consolidation

Freight consolidation is an excellent strategy for optimizing shipping costs. By combining smaller shipments into a larger load, businesses can take advantage of reduced per-unit transportation costs. This approach not only achieves economies of scale but also minimizes the number of trips required, thereby reducing overall shipping expenses. Additionally, freight consolidation helps improve the load factor of vehicles, enhancing environmental sustainability by lowering carbon footprints. To effectively implement this strategy, consider using freight forwarders or third-party logistics providers who can offer consolidation services tailored to your needs. According to East West Manufacturing, this method can significantly cut down logistics costs.

Moreover, leveraging existing networks and building partnerships with other businesses that share similar shipping routes can enhance your consolidation efforts. Cooperation within industry clusters allows companies to align their shipping needs, further streamlining operations. This can be particularly advantageous for businesses with irregular shipping schedules, where collaboration leads to consistent shipping volumes—essential for maximizing consolidation benefits. Thus, creating strategic alliances in the supply chain not only strengthens logistics efficiency but also facilitates financial savings.

3. Negotiate with Carriers

Just like in any long-term relationship, building rapport with your carriers can be mutually beneficial. Carriers value steady business, and the more dependable you are as a customer, the better rates and terms you can potentially negotiate. Using your company’s shipping volume as leverage during discussions can unfold avenues for discounted rates, priority services, or even premium benefits. Staying informed about the industry trends helps significantly in these negotiations. For instance, understanding factors such as seasonal variations in sea freight rates can also empower you to strike the most favorable deals.

In addition, consider engaging multiple carriers and regularly comparing their offerings. This doesn’t mean you need to switch carriers often, but knowledge of the market can put you in a strong negotiating position. It’s about finding the right balance to ensure the best services at the most competitive prices. Communicating clearly your service expectations, such as transit times, reliability, and handling standards, will align your interests and establish a solid business relationship with your carriers.

4. Implement Technology Solutions

The adoption of technology in logistics is not just a trend; it’s a necessity. Implementing advanced logistics management software can streamline operations, offering real-time tracking and data analytics capabilities that significantly enhance decision-making. Automation is another critical component—by automating routine tasks, your team can focus on strategic planning and exception management, rather than being bogged down by day-to-day operations. Park, tracking, inventory management, and even customer communication can be automated to reduce errors and improve efficiency. Technologies such as RFID, IoT devices for tracking shipments, and AI-powered analytics platforms are just a few of the tools propelling logistics into a new era.

5. Utilize Local Distribution Centers

Establishing distribution centers closer to your customer base can markedly reduce last-mile delivery costs, which are often the most expensive leg of a shipment. This not only minimizes the distance packages travel, cutting back on fuel consumption and its associated costs, but also leads to quicker delivery times, enhancing customer satisfaction. By analyzing customer demographics and sales data, businesses can strategically choose distribution center locations that match their market demand centers, streamlining logistics operations and ensuring efficient inventory turnover. This strategic placement of goods is crucial for maintaining a competitive edge in the digital marketplace, offering both cost savings and improved service levels.

6. Outsource Non-Core Activities

Outsourcing logistics activities can be a viable option for companies looking to streamline operations and cut costs. By delegating non-core functions such as warehousing, transport, and order fulfillment to third-party logistics providers (3PLs), a company can concentrate on its central business processes, ensuring better overall efficiency. These providers bring specialized expertise, technology, and economies of scale that can be more cost-effective than in-house operations. They also offer flexibility and scalability, allowing businesses to adapt quickly to changing market conditions without incurring heavy capital investments.

Choosing the right 3PL partner is critical. Assess their capabilities, reliability, and compatibility with your business ethos and requirements. Long-term success is often built on trust and shared objectives, so investing time in vetting potential providers is paramount. Look for partnerships that evolve with your business needs, providing insights into efficiencies that can be gained, and offering innovative service solutions. By finding a partner aligned with your strategic goals, you ensure that the logistics end of your business can evolve alongside your growth trajectory, remaining an asset rather than a potential liability.

7. Adopt Intermodal Shipping

Intermodal shipping represents the use of multiple modes of transportation—such as trucks, rail, and ships—to move goods, each benefitting from its strengths to achieve cost-efficient and faster delivery times. By ensuring seamless transitions between modes, intermodal shipping can manage costs effectively while maintaining shipment integrity. Companies leveraging this approach can alleviate capacity constraints often seen in a single mode, such as trucking, by adding rail or maritime routes. This flexibility becomes particularly useful in times of seasonal demand peaks or unforeseen disruptions in one mode of transport. Moreover, diversifying transport means can offer sustainability benefits, as rail and maritime options typically offer reduced emissions compared to road freight, aligning with growing green initiatives.

Selecting the right combination of transport and reliably managing the connections is where the real savings and efficiencies come into play. Developing a partnership with logistics providers who specialize in intermodal transport can optimize these arrangements. Additionally, investing in technologies capable of forecasting and tracking performance across different transport modes provides complete control over your supply chain. East West Manufacturing highlights how combining these transportation methods can significantly enhance both cost efficiency and service reliability.

8. Utilize Reverse Logistics

Reverse logistics, the process of moving goods from their final destination for the purpose of capturing value, or proper disposal, provides a unique opportunity to recoup costs and reduce waste. Properly managing returns, recycling, and disposal operations helps to recapture value through refurbishment, resale, or recycling. Implementing effective reverse logistics strategies involves an understanding of the entire product lifecycle and the channels through which goods can re-enter the supply chain. This can be surprisingly cost-efficient, as it not only minimizes the costs of returns but can also enhance customer satisfaction through simplified return processes.

9. Optimize Packaging

Optimizing your packaging is a straightforward yet powerful way to reduce logistics costs. The goal here is to utilize materials that offer the best protection at the lowest weight and volume. Look for solutions that minimize wasted space and use eco-friendly alternatives that can decrease waste disposal costs. Adopting advanced packaging solutions not only saves money on raw materials but can significantly reduce shipping costs associated directly with weight and size. Design engineering teams, working in tandem with your logistics department, can innovate in developing solutions that integrate product protection with cost-efficiency effectively.

It’s not just about cost savings, but about aligning your brand’s environmental responsibility with the growing consumer demands for sustainable practices. Consider biodegradables or recyclable materials, which could potentially lower costs further down the supply chain, such as those associated with reverse logistics and customer handling. Additionally, packaging that is consciously designed often results in reduced damage rates during transit, contributing to overall lower logistics costs by decreasing the need for returns and replacements. This multifaceted approach can uniquely position a brand well with consumers, who appreciate both cost-consciousness and environmental stewardship.

10. Focus on Compliance and Regulations

Navigating the complex web of international shipping regulations is no small task. Ensuring compliance helps businesses avoid costly fines and delays, as improper documentation or non-compliance with regional rules can result in seizures, fines, and significant disruption to your supply chain. Therefore, maintaining accurate and thorough documentation is crucial. Investing in compliance management software or engaging with experts in international trade can ensure that your operations remain within legal bounds. This approach not only facilitates smoother customs clearance but also reinforces your business’s reputation as a reliable international trader.

Be proactive in learning about the specific regulations and potential changes that might affect your operations. This knowledge can open up opportunities for better financial planning and operational adjustments ahead of enforced policy shifts. By staying informed and adaptable to regulatory nuances, you position your business for seamless and cost-effective transitions when exporting or importing globally, a point highlighted in our article on avoiding pitfalls in importing.

11. Improving Supplier Relationships

Building robust relationships with suppliers is integral to cost-efficient logistics operations. These relationships are not just about negotiating prices; they’re about fostering mutual trust and collaboration. When suppliers feel valued, they are more likely to offer favorable terms, prioritize your shipments during high-demand periods, and provide insights into market trends that could impact your supply chain. An open line of communication ensures that any changes in demand or supply can be swiftly addressed, minimizing disruptions and associated costs.

12. Invest in Training and Development

Continuous training and development within your logistics team create a competent workforce capable of navigating the complexities of international logistics with ease. By staying abreast of the latest trends and technologies, your team can not only improve efficiency but also identify and implement cost-saving initiatives actively. Understanding geopolitical landscapes, compliance requirements, and technological advancements empowers your staff to make informed decisions that align with strategic business goals, as emphasized in our insights on international logistics transforming the marketplace.